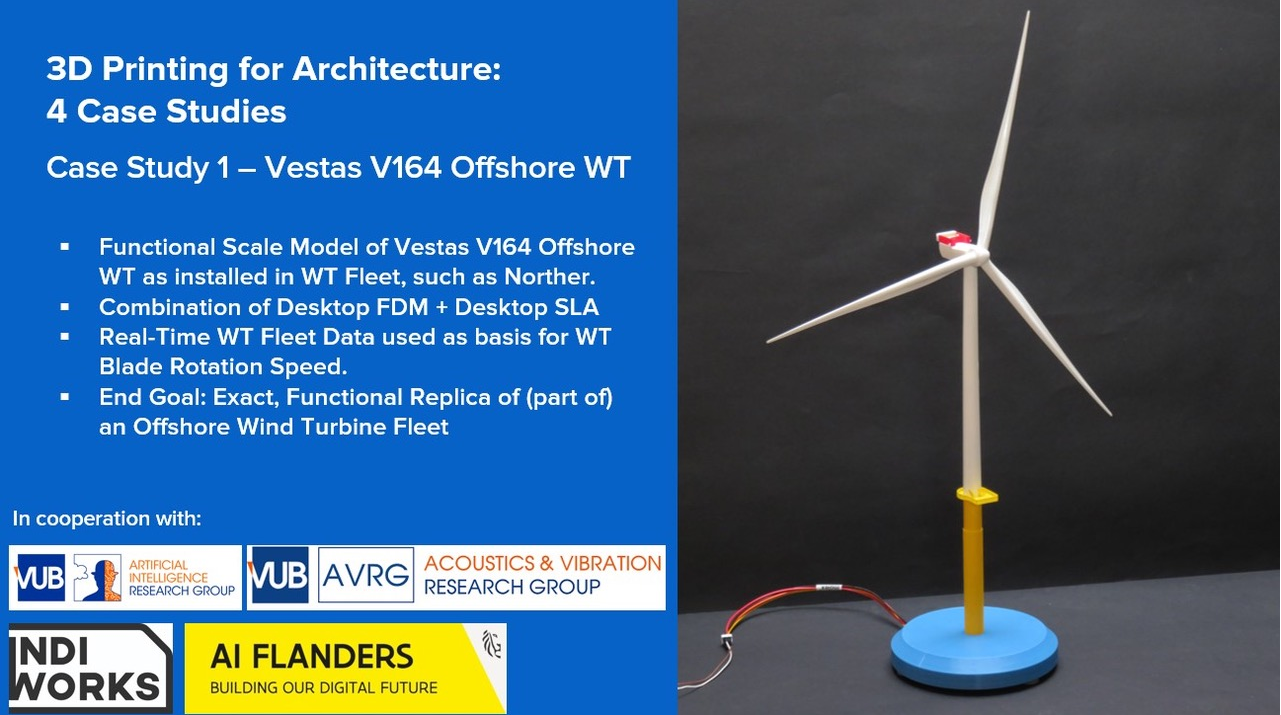

Recently, the AI lab, VUB’s Acoustics & Vibration research group (AVRG), INDIWORKS and PrintPlace set up a collaboration to design and build a fully functional scale model of the Vestas V164 Offshore Wind Turbine. The main goal of this collaboration is to build a scale model of a windfarm which shows its real-time condition like speed of the blades based on real-time data.

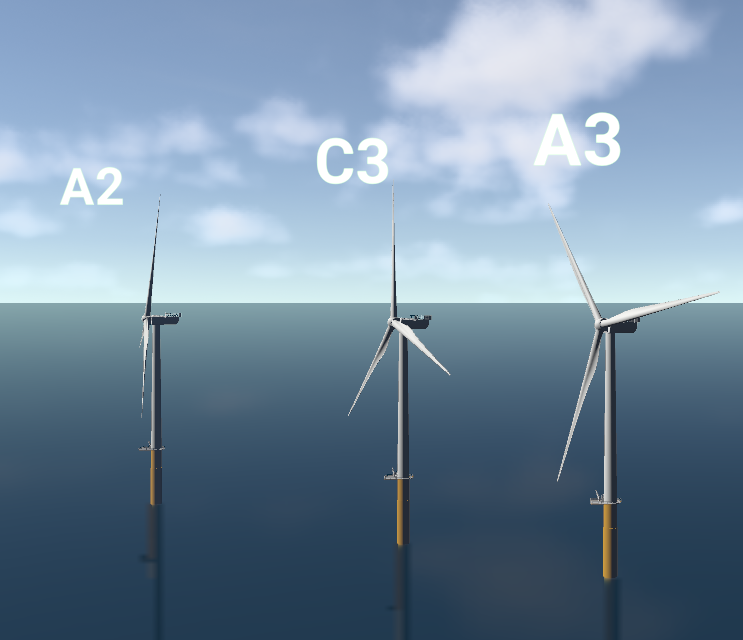

This project connects seamlessly with the joint research project between the AI lab and AVRG’s Offshore Wind Energy group in which we investigate how multi-agent reinforcement learning techniques can be used to develop a wind farm controller that predicts stressful situations and coordinates the wind turbines in order to prevent problems. For instance, storms have a negative effect on the health of a turbine and it is challenging to predict how these turbines should react to a storm. By letting the turbines communicate and coordinate among each other, we can reduce potential failures and thus decrease operation and maintenance costs. Very soon the AI lab will also launch a new demo in which you can see these reinforcement learning algorithms in action. The demo is made with Unity and uses the corresponding 3D model of the above-mentioned Vestas V164 Offshore Wind Turbine.

On September 6 4PM CEST, the Vestas V164 Offshore Wind Turbine will be one of the case studies in the 3D Printing for Architecture Modelling webinar organised by Formlabs, one of the largest Desktop 3D Printing producers world wide. The webinar will be streamed globally, you can sign up using this link.